Mitchell Lewis & StaverMitchell Lewis & Staver

Engineering Pump Efficiency

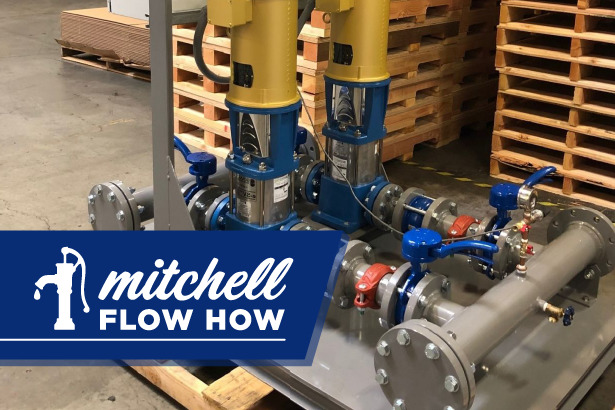

Booster Pumps

- Energy-efficient pumps that maintain water pressure in areas with low or fluctuating water pressure

- Built to last and designed for continuous operation

- Available in stock or as a custom engineered packaged system

What are Booster Pumps?

Many types of pumps function as booster pumps depending on the application. Fluid is drawn into the pump and its pressure is increased as it passes through the impeller and diffuser casing, which converts velocity head from the impeller into pressure head.

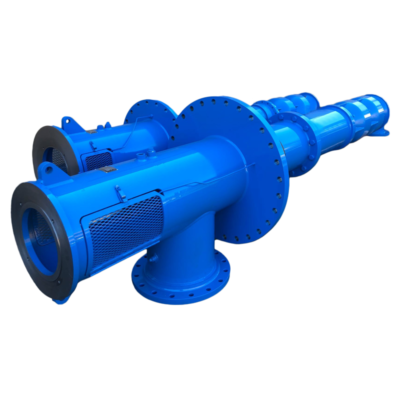

Horizontal Multi-Stage Centrifugal Pumps

For increasing the pressure of liquid that is already flowing

Vertical Multi-Stage Centrifugal Pumps

Centrifugal pumps with multiple impellers for higher pressures.

End Suction Centrifugal Pumps

Highly configurable pump for parallel and in-line applications.

Canned Lineshaft Turbine

Powerful efficiency for applications with inlet pressure or existing suction pipe.

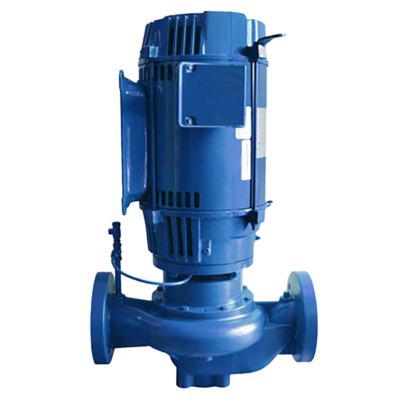

In-line Centrifugal Pumps

Simple piping and smaller footprint for in-line boosting.

Boosters are employed in a variety of applications and often in combination with vertical turbine pumps or vertical submersible pumps to further boost the pressure (head) of irrigation or drinking water being pumped from wells.

Booster pumps are also used in pipelines to add pressure (head) to move the liquid along to the next pump or to its final destination at the end of the pipeline. And they are used in many process applications, where the pressure (head) required for the service is more than one pump can deliver, or where a second pump is required to make sure that the pumps do not cavitate.

Single-stage boosters are generally used in applications where the amount of additional pressure required is moderate, such as private residences or buildings that are far from the municipal water supply. They’re also useful for irrigation systems if the well pump doesn’t have sufficient pressure (head) for the distance the water needs to travel.

Multi-stage configurations deliver higher heads such as would be required to move water up to substantially higher elevations or through much longer pipelines.

Types of booster pumps include: vertical and horizontal multi-stage, split case & submersible multi-stage.

Questions? We’re here to help

See Our ServicesSign Up for E-News

Get news on the latest promotions, events, resources and more!

"*" indicates required fields