Mitchell Lewis & StaverMitchell Lewis & Staver

Engineering Pump Efficiency

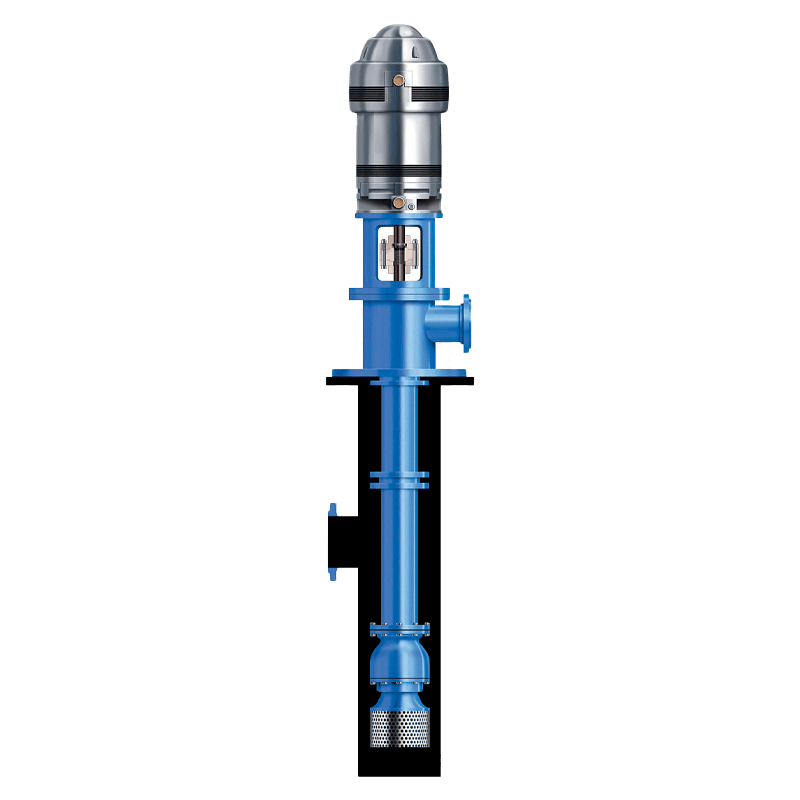

Canned Lineshaft Turbine

Canned Lineshaft Turbine

- In-ground booster

- Can achieve very high flows and very high heads

- Robust design, wider performance window, with steeper curve

- Product (water) lubed or oil lubed

Applications

- Agricultural Irrigation

- Municipal water supply

- Booster System

Features

| Bowl Sizes | 6-24" + |

| Flow | up to 10,000 GPM |

| Head | up to 1,000 FT |

| Column Length | 30 FT |

| HP Required | up to 1,000 HP |

| Power Supply | electric motor, diesel/gas engine |

| Liquid Types | clean/fresh water, sea water, mine dewatering |

| Temperature | 36-178 F |

Features & Benefits

Can turbines are used as boosters in a pumping system. They are typically water lubed short set turbines with a discharge head that has a machined base that mates to an ANSI flange on the top of the can. This configuration uses gravity to increase the amount of suction pressure available to the pump, allowing them to operate effectively as a booster pump using minimal floorspace.

Can turbines offer a vast variety of flow and head options and can achieve very high flows and very high heads.

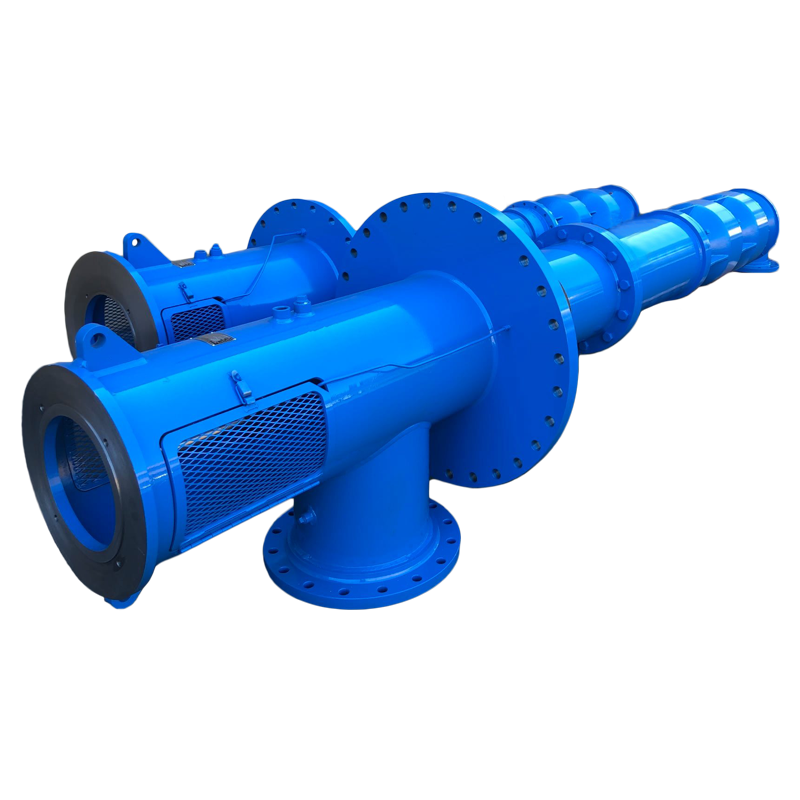

T- Style: This style of head allows the plumbing to be in line with the pump and simplifies installation.

FF/DL-Style: When using a type FF head or a type DL (Ductile iron), the inlet is below ground so excavation is required.

The Goulds DL head is limited to a specific can size based on the head size. The fabricated steel heads can be configured as required.

Can turbines are expensive compared to centrifugal pumps but offer a more robust design and a wider performance window with steeper curves. Can turbines are better suited for use with a VFD.

Product Resources

For General Information, Terms & Conditions, Performance Curves and Engineering Data, please reference our manufacturer’s resources.

Questions? We’re here to help

See Our ServicesSign Up for E-News

Get news on the latest promotions, events, resources and more!

"*" indicates required fields